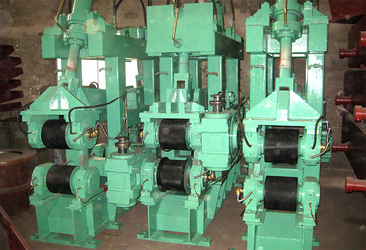

Continuous Casting-Stretching and Straightening Machine

Description

Function and Structure

During casting, the straightening machine continuously pulls out and straightens the curved strand. During dummy ingot delivery, the straightening rollers rotate in reverse to feed the dummy head into the mold.

This single-frame, five-roller continuous straightening and straightening machine produces continuous and uniform deformation of the strand at a low and steady rate, eliminating peaks in straightening deformation. This significantly reduces surface and internal crack defects in the strand, making it suitable for high-speed and large-section strand production.

The straightening machine consists of drive rollers, driven rollers, a transmission mechanism, a frame structure, a water-cooling system, and a water-cooling protective wall.

Main Parameters

Type: Five-roller Continuous Straightening Machine

Applicable Sections: 100×100, 120×120, 130×130, 150×150

Drive Motor:

Power: 7.5kW – YZP132M-4 (Variable Frequency)

Speed: Nominal 1440r/min

Reducer: Total Speed Ratio: 1:320

Drive Rollers: Quantity: 2, Diameter: 300mm, Internally Water-Cooled

Driven Lower Rollers: Quantity: 3, Roller Material: 42CrMo

Reviews

There are no reviews yet.