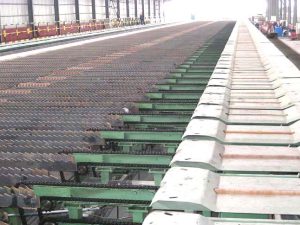

R6m-4 machines 4 streams arc continuous caster

Billet continuous casting is a fully mature technology. Among existing billet casting machines, curved-type machines dominate. In particular, with the exception of a very small number of extra-large billet casting machines, nearly all newly built billet casting machines are curved. The primary difference among curved-type billet casting machines lies in the type of dummy bar….